Safety testing and effective client reporting

are our core services

Our extensive list of clients include businesses of all types and sizes (single or multiple sites) and in both the private and public sectors.A risk assessment will help you have a better understand of your safety testing needs. It is a process to identify potential hazards, model risks and analyse outcomes. A business impact analysis (BIA) is the process of determining the potential impacts resulting from the interruption of time sensitive or critical business processes.

The ultimate purpose of a risk assessment is to improve workplace health and safety. To achieve this, the risk assessment process needs to identify workplace hazards and reduce or eliminate the risks they pose.

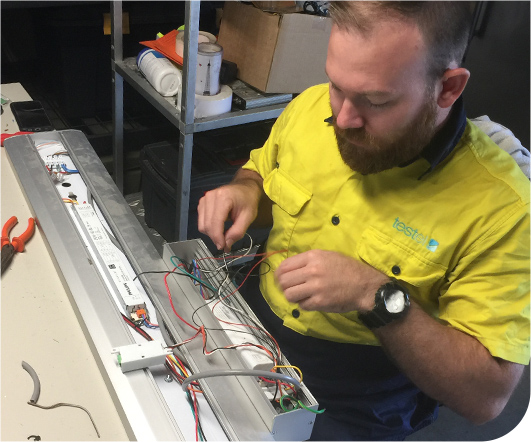

Electrical safety test (Test and tag)

Reducing the risk of shocks, fire, circuit overloading and accidents, electrical safety testing ensures equipment and devices are reliable and meet the health and safety requirements. Routine electrical testing also acts as a preventative maintenance tool to identify defective items before they are the cause of damage and costs.

In order to protect your equipment, we

- perform a mechanical inspection.

- apply electrical test loads which examine wiring, earthing, bonding, defective work and invisible electrical faults to establish compliance.

- apply a tag to the equipment.

- prepare records using our proprietary TES data management software to report results (pass or fail) and repairs undertaken.

The regular maintenance program is set out in Australian Standards AS/NZS 3760 In-service safety inspection and testing of electrical equipment and RCD’s.

RCD test (Safety switch or ELCB)

RCDs are used to promote safety, providing an additional defence against electric shock as they are more sensitive than a normal fuse or circuit breaker.

RCDs monitor the level of electrical current within a circuit. At any stage when the RCD detects a peculiarity, it will instantaneously cut off the circuit. RCDs save many lives and prevent injuries, so it is necessary to ensure they are working properly at all times. This is where RCD testing comes into play. There are different types of RCDs and they are all subject to the same RCD tests.

push button test – will ensure the RCD will trip when required.

time test – which simulates a current leakage fault to measure the time taken to trip or ‘cut-off’ the current.

The regular maintenance program is set out in Australian Standards AS/NZS 3760 In-service safety inspection and testing of electrical equipment and RCD’s.

RCD test (Safety switch or ELCB)

RCDs are used to promote safety, providing an additional defence against electric shock as they are more sensitive than a normal fuse or circuit breaker.

RCDs monitor the level of electrical current within a circuit. At any stage when the RCD detects a peculiarity, it will instantaneously cut off the circuit. RCDs save many lives and prevent injuries, so it is necessary to ensure they are working properly at all times. This is where RCD testing comes into play. There are different types of RCDs and they are all subject to the same RCD tests.

push button test – will ensure the RCD will trip when required.

time test – which simulates a current leakage fault to measure the time taken to trip or ‘cut-off’ the current.

The regular maintenance program is set out in Australian Standards AS/NZS 3760 In-service safety inspection and testing of electrical equipment and RCD’s.

Microwave leakage test

A microwave oven generates microwave rays which pass through food and liquid and react with and agitate the liquid molecules. The agitation results in the liquid molecules moving faster generating heat. In the same way microwave rays affect the human body and scientific research demonstrates the effects of radiation on the central nervous system and brain metabolism.

A microwave oven deteriorates through normal use and regular testing identifies when the emitted radiation is no longer at accepted levels. Microwave leakage testing involves:

- a visual inspection to identify any physical defects that contribute toward leakage.

- the radiation leakage test which measures the emission levels from the microwave unit.

- recording of the findings to track the performance of the microwave unit over time.

Fire equipment test

Fire equipment (fire extinguishers, fire blankets and hose reels) testing is an essential safety service offered by us. Regular testing ensures that the fire equipment is ready when needed. Testing of fire equipment is conducted according to the Australian Standard AS 1851.

- extinguishers are tested on a 6 monthly cycle.

- extinguishers are visually inspected to assess their physical accessibility, mounted height and other mechanical limitations.

- extinguishers are pressure tested and replaced as required.

- results are recorded on an affixed tag and also in TES.

Fire equipment test

Fire equipment (fire extinguishers, fire blankets and hose reels) testing is an essential safety service offered by us. Regular testing ensures that the fire equipment is ready when needed. Testing of fire equipment is conducted according to the Australian Standard AS 1851.

- extinguishers are tested on a 6 monthly cycle.

- extinguishers are visually inspected to assess their physical accessibility, mounted height and other mechanical limitations.

- extinguishers are pressure tested and replaced as required.

- results are recorded on an affixed tag and also in TES.

Emergency and exit light test

The Australian Standard requires that all such lighting systems must be operational and in a state of readiness. Like any emergency equipment, testing must be a routine procedure. Our emergency and exit light test service includes inspecting and repairing (as required and applicable):

- switches and batteries

- luminaries and tubes

- control equipment

- cleaning and maintenance

- ensure lighting can remain lit for a minimum of 90 minutes

- reporting of failures

- recording findings and results

The regular maintenance program is set out in Australian Standards AS/NZS 2293.2 – Emergency lighting and exit signs for buildings routine service and maintenance and AS/NZS 2293.3 – Emergency lighting and exit signs for buildings emergency luminaires and exit signs.

Thermal imaging

Thermal imaging’s ability to detect temperature differences assists in electrical safety testing as heat differences can signal an electrical fault within a device or appliance that is often invisible to the eye.

Typically used to test electrical/mechanical services, switchboards and equipment, thermal imaging is especially useful as switchboard faults often break down over time, providing the owner with a period of time in which to identify the fault before any serious issues occur. For this reason thermal imaging is considered a form of preventative maintenance.

All our thermographers are qualified to ISO 18436-7: Condition monitoring and diagnostics of machines requirements for qualification and assessment of personnel Part 7: Thermography, and follow the principles set out in ISO 18434-1: Condition monitoring and diagnostics of machines — Thermography — Part 1: General procedures.

Thermal imaging

Thermal imaging’s ability to detect temperature differences assists in electrical safety testing as heat differences can signal an electrical fault within a device or appliance that is often invisible to the eye.

Typically used to test electrical/mechanical services, switchboards and equipment, thermal imaging is especially useful as switchboard faults often break down over time, providing the owner with a period of time in which to identify the fault before any serious issues occur. For this reason thermal imaging is considered a form of preventative maintenance.

All our thermographers are qualified to ISO 18436-7: Condition monitoring and diagnostics of machines requirements for qualification and assessment of personnel Part 7: Thermography, and follow the principles set out in ISO 18434-1: Condition monitoring and diagnostics of machines — Thermography — Part 1: General procedures.

First aid kit

It is employer’s responsibilities to provide first aid that include the following:

- supplying first aid equipment

- providing access to first aid equipment

- provide trained first aiders

We will provide you with the required first aid kit.

The first aid kits are specific to their application in a fixed workplace, a mobile workplace or a vehicle.

Repair and replacement

We are able to provide an extensive range of electrical safety tests to identify the source of the problem prior to repairing it. Our technicians are qualified to repair faulty electrical equipment. If it is practical and cost-effective to repair a faulty item, we provide recommendations to our customers and carry out our repair service according to your requirements.

Repair and replacement

We are able to provide an extensive range of electrical safety tests to identify the source of the problem prior to repairing it. Our technicians are qualified to repair faulty electrical equipment. If it is practical and cost-effective to repair a faulty item, we provide recommendations to our customers and carry out our repair service according to your requirements.

Reporting and record keeping

Record keeping and compliance obligations are relied upon to demonstrate an employer’s commitment to maintaining a health and safety conscious workplace. These are time consuming tasks which are non-revenue raising that are generally completed by technically trained and competent employees.

All reporting and record keeping will be managed by our experienced in-house staff. In the normal course of business, we will undertake the testing, servicing and repair work and record results in our own database – TES. Test results are available in hardcopy form, electronic form and can be easily downloaded via our client portal.

Preventative maintenance schedule and reminder

As sites or assets fall due for servicing, Testel removes the hassle by providing reminders which is very much a ‘set and forget’ service. The Testel proprietary database, TES flags sites and assets as they fall due and generates automatic reminders providing advance notice. The reminders are sent to the decision maker/s within your company and capture all sites. This has an increasing benefit for increasing site numbers and TES will flag 1,000+ sites across Australia that are due throughout the year including metropolitan sites, regional sites and remote sites. Budget costs or projected costs are calculated in advance using forward projections.

Preventative maintenance schedule and reminder

As sites or assets fall due for servicing, Testel removes the hassle by providing reminders which is very much a ‘set and forget’ service. The Testel proprietary database, TES flags sites and assets as they fall due and generates automatic reminders providing advance notice. The reminders are sent to the decision maker/s within your company and capture all sites. This has an increasing benefit for increasing site numbers and TES will flag 1,000+ sites across Australia that are due throughout the year including metropolitan sites, regional sites and remote sites. Budget costs or projected costs are calculated in advance using forward projections.

Records and reminders

We manage 25,000+ sites requiring regular servicing covering an extensive range of plant and equipment. Testel operates throughout Australia serving metropolitan, regional and remote sites. Records collected include:

- asset number

- type of tests conducted

- where the test was carried out / location

- description/manufacturer of the plant or equipment

- date tested

- date of next test

- test result

TES – our data management software flags sites as they become due, creates lists of equipment due and generates reminder notices that are sent to clients.

TES – Management software

TES, our in-house developed database is a powerful digital management tool with a range of features which significantly reduce testing and reporting time. The data integration and the streamlined workflow will reduce service costs whilst enhancing the accuracy and quality of our service.

You can view a range of reports on your own computer including performance reports, budget forecasts, test results etc. The live data integrations will provide you with on-demand data and track safety management related activities anytime, anywhere.

TES – Management software

TES, our in-house developed database is a powerful digital management tool with a range of features which significantly reduce testing and reporting time. The data integration and the streamlined workflow will reduce service costs whilst enhancing the accuracy and quality of our service.

You can view a range of reports on your own computer including performance reports, budget forecasts, test results etc. The live data integrations will provide you with on-demand data and track safety management related activities anytime, anywhere.

We are trusted by

Reece Group

“The Reece Group have employed Testel to test and tag electrical equipment at a range of sites across Australia since at least 2010. The technicians follow our policies, ring ahead to our sites and undertake all required tasks efficiently. All our communications with the Administrative and Sales Team have been effective, with prompt responses and clear communication demonstrated in a very professional way.”

Bendigo and Adelaide Bank

“Testel have been very easy to deal with, they provide a great combined services helping our customers maintain compliance with ease and efficiency. Complimented by friendly staff who are willing to go the extra mile.”

Super Retail Group

“Testel carries out the testing and tagging of electrical items in Australia across all of our brands. We have partnered with Testel for over 10 years as we find them very reliable, with excellent reporting and communication.”

BGIS/Optus

“We developed a great partnership with Testel. The team work across 200+ sites nationally, are always responsive to any questions we have and are easy to work with. Simon provides a great service and often meets with the team onsite to ensure we are all aligned. Great service all round from Testel and the team.”

FAQs

Why should electrical equipment be tested?

The reasons for conducting electrical inspections and electrical testing are varied. However, it is apparent that the dangers associated to using electricity and electrical products both as a consumer and worker led to a regime to develop good industry practice which is in addition to any legal requirement that exists.

Due simply to normal use electrical equipment can develop a fault, stop working or become dangerous without any signs and can cause damage to other equipment.

How often should appliances be tested and tagged?

The Australian Standards detail particular test and tag frequencies that are based upon both the type of electrical item and the environment the item is used. This varies depending on a workplaces individual risk assessment.

Once we have your items listed on our database, our client support will give you a friendly and timely reminder before the next test’s due date to ensure that all your equipment is in line with the Australian Safety Standards.